We all are aware of the feeling of disappointment when we buy an expensive branded dress, and after the first wash, it loses its size. It always turns you off, especially if you get your clothes stitched yourself. The brand should not be held accountable for that because it happens due to a phenomenon known as dimensional stability in fabrics. It is a problem that almost every small to large-scale textile industry faces with its production. One can not prevent it; instead, we can fix this issue as much as possible and gain customer satisfaction.

Before digging into the solutions, first, have an insight into what goes behind the fabric shrinkage.

What is Fabric Shrinking?

An increase or decrease in the dimensions of fabric is called fabric shrinkage. When a fabric is being made in the industry, it goes through a series of processes. These processes include the lengthwise and widthwise stretching of the cloth which results in the build-up of stress in the material. When it comes in contact with moisture, it shrinks because water acts as a relaxing medium for the threads that make up a fabric. The relaxation process affects the material and changes its dimensions. As a result, the cloth either decreases in size or increases a bit.

What causes Fabric Shrinkage?

There are plenty of causes that result in the shrinkage of fabrics. Let’s give you a tour of what happens in the textile industry for a more precise idea. Cotton, which is the raw material of textile factories, is a cloud-like mushy ball. You must have thought that how does it transform into colored, plain, or printed stuff? So basically, It goes through a series of processes. Different machines are responsible for this metaphysical conversion of raw material into smooth, soft yet vivid products. The method includes the conversion of fiber into yarn, and then a cloth is made out of that yarn. The threads are put together chemically through hydrogen and ionic bonds. This cycle of mechanical functions that include spinning, knitting, dyeing, and finishing causes a build-up of stress and strain in the material.

After going through the manufacturing process, the fabric is exposed to the water, also known as the relaxing medium. It is supposed to be soaked for about 6 to 8 hours roughly for adequate shrinkage. The immersion results in the garment’s relaxation shrinkage. It occurs due to the release of the strain from the threads. It leads to the dimensional reduction of the fabric. The shrinkage is further defined into different types, which are so extensive to be explained here; that is another article’s topic.

Material Matters

Relaxation shrinkage occurs in the products made from literally ANY textile fiber. Every material has a different tendency to lose its size upon exposure to the relaxing medium. A decrease in size often occurs but an increase in size is quite rare in the fabrics. Moreover, every process of manufacture plays its role and affects the rate of overall shrinkage. Generally, it depends on the thickness of the cloth and the fittings of the weaves. The rate of shrinkage depends from fabric to fabric. The piece of woven fabric shrinks less than a piece of knitted fabric. Similarly, a piece of linen fabric shrinks more than a piece of cotton fabric.

Fabric Attribute

A lot of attributes play their part in the shrinking of fabrics. For example;

· Moisture content absorption

The inclination of a piece of cloth to absorb moisture can impact its ability to shrink. A fabric, no matter how condensed its weaves are it still has tiny holes in it. These holes can be seen in sunlight. Any material with holes absorbs water quickly and easily, as in sponges. This property of clothes makes them highly absorbent of liquids, and thus the rate of shrinkage is much likely in them. Cotton has the highest absorbance rate that is why it shrinks the most.

· Tension in Fabric

It is common for a knitted fabric to increase in size as soon as a little amount of force is applied in the factory. A 100 percent interlocked fabric might change about 10% after each mill processing step. The more stretch is provided and tension accumulates between the weaves, the more it will relax and reduce in size.

· Density of Fabrics

A density of cloth is described as the yarn layers put together to make a thick cloth. A thick fabric soaks slowly and becomes more decadent because of the dense structure of interwoven threads. The density is measured in inches, and it affects the shrinkage process. Cambric is a typical example of the thickest fabric. A dense piece of cloth shrinks 5 percent in total. It shrinks every time while washing and drying if it is not adequately pre-shrunk while manufacturing.

· The Thickness of the Yarn

There are different kinds of yarns. Every yarn is made with a purpose. For instance, a sports yarn is made for making gym clothes and sports merch. Similarly, lace yarn is made for making delicate pieces for adorning your apparel. The thicker a string is, the thicker and stronger its weaves would be. It is hard to break them or tear a product made out of them. Deswelling of yarn occurs when a cloth is immersed in the water and shrinks.

· Fiber Structure

Yarn is made up of hundreds of tiny fibers put together. Like all the other physical factors, these fibrous strands and their intertwining are also responsible for the overall percent of shrinkage in a fabric. The way these fibers are oriented in yarn will affect certain fabric elements, most important of which is the rate of shrinkage. Yarns with high twists will generate higher shrinkage values, whereas those with lower twist levels will not.

Washing Temperature

The washing temperature of the water plays a vital role in the cloth’s life. That is why a lot of ready-made clothes come out with a guide to wash. Hot or warm water significantly impacts the shrinkage process and makes it faster. Once you have washed your clothes in warm water, they will shrink as much as possible and will never shrink in the second or third wash after that. Technically it is excellent to preshrink your fabric before sending it to the tailors, but if you are doing it after it is stitched, then I am sorry in advance for its consequences. Hot water is incredible for removing dirt and germs, but it is an offender for size. The garments’ washing temperature should remain moderate to protect the clothes from worn-ing out and losing their color.

Finishing process of the fabric

Finishing refers to the process that makes the knitted or woven fabric wearable by giving it a polished look. This is as the name shows the last stage of the process. It includes the washing, drying, and pressing of the fabric to make it more presentable. It is done to earn the first impression. Industries now sell pre-shrunk materials, and that is also done during the finishing process. Extended exposure to warm water at a temperature of about 110°F to 90°F can shrink the fabric considerably.

The finishing process is very crucial for the textile industries in gaining the confidence of their clients. It helps them make their reputation among the big fat garment retailers to become their regular customers.

Shrinkage rates of different textures

Every material feels different on the skin. In winters, the clothes make us warm and cozy, and in summers, they feel light and breezy on the body. A piece of fabric is made different from the others by how tiny fibers are entwined, the yarn is interwoven, and the way they are put loosely or closely together to make the derivative fabric. These little differences entirely transform the texture of the cloth. It leads to every material having different physical and chemical properties, including their rate of shrinkage. A comparison of a few standard fabrics and their percentage of shrinkage is given below.

| Different types of Fabrics (natural/synthetic) | Average Shrinkage Rates |

| Cotton fabric | 4 to 10 percent |

| Linen fabric | 2 to 7 percent |

| Polyester fabric | Zero percent |

| Rayon fabric | 5 to 10 percent |

| Chiffon fabric | 2 to 3 percent |

| Silk fabric | 10 to 15 percent |

| Twill fabric | 4.0 to 4.9 percent |

| Poplin fabric | 3.3 to 4.5 percent |

Natural fibers versus Synthetic fibers

Natural fibers shrink way more than their human-made equivalents, known as synthetic fibers. Natural fibers have an amorphous structure that gives space for the water to seep in and trigger the shrinking tendency. Synthetic or artificial fibers have a crystalline and thermoplastic nature with a zero to no chance of orifices for the water to flow into and increase the shrinking tendency. Ryon, nylon, acrylic, polyester, and spandex are examples of fabrics made out of synthetic fibers. Cotton, sheep wool, cashmere, silk, and linen are examples of natural fibers’ materials.

How to do Shrinkage Testing

You can do testing of shrinkage rate with the help of some formulas. An average percentage inferred after the calculation tells us about the dimensional gain or loss. There are several ways to test the rate of shrinkage in a specific fabric. A few of them are given below.

Test by personal means

It should be tumble washed in a washing machine at a gentle speed with hot water for checking a fabric shrinkage. The temperature of the water should be above ninety-degree Fahrenheit. Washing for about two intervals and then tumble drying the fabric in the dryer for 5 minutes assists the process of shrinking. It makes it easier and faster. Within 35 to 40 minutes, you can test the overall tendency of a texture to shrink. It is the common and the most reliable way of shrinking clothes in most parts of the world.

The dimensions of the cloth should be appropriately measured before washing and drying it. After doing the entire process, you should retake the measurements. A subtraction between the two roughly gives you the rate of shrinkage. It would be best if you took an average percentage out of the result for convenience. The shrinking can occur either horizontally, vertically, or both. Moreover, it can either increase or expand in size, known as plus shrinkage, or instead go through a decrease or contraction in size, known as minus shrinkage. If the result shows a little to no loss/gain of size, it means that the fabric is excellent and ready to be sold to garment retailers.

Test by the third party

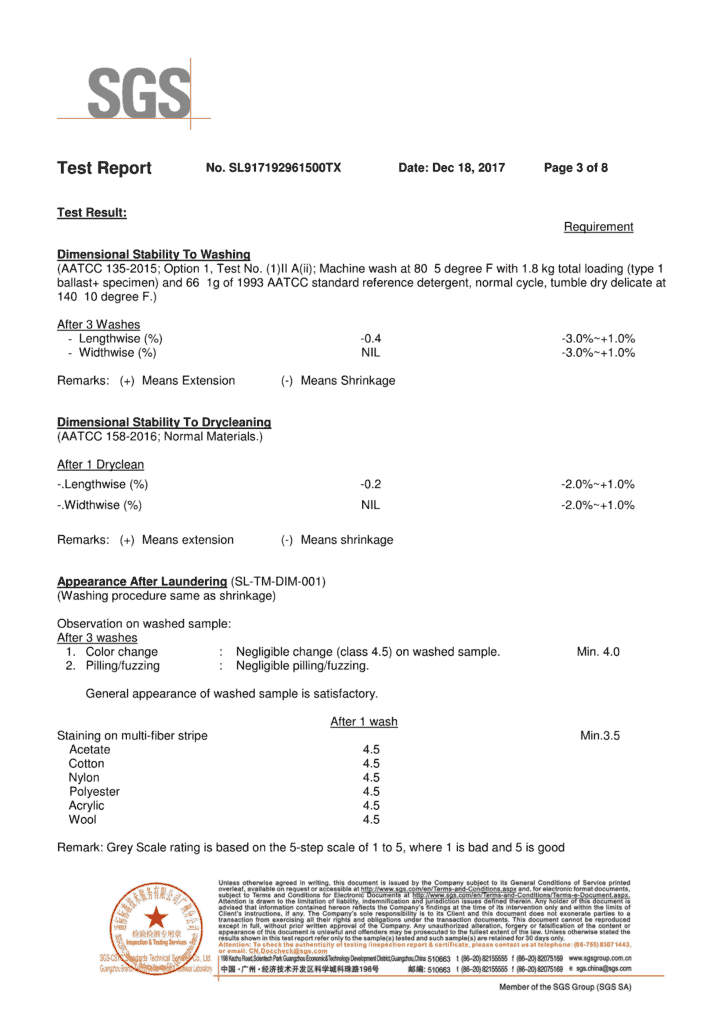

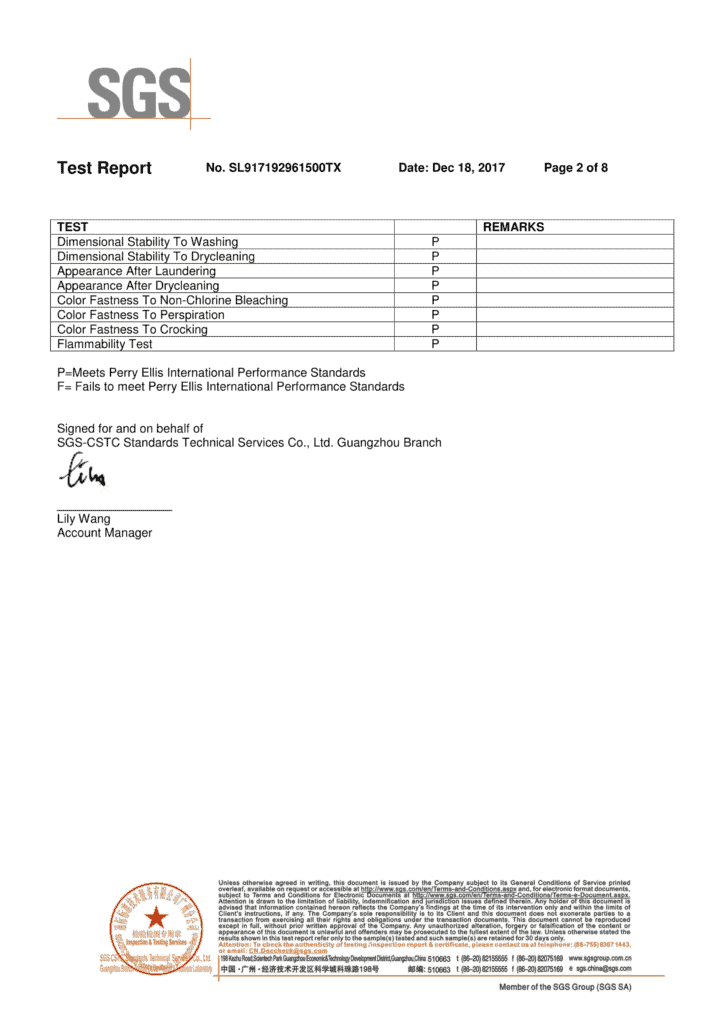

Another way to test the fabric shrinkage is done by large-scale companies made to serve the purpose of screening fabrics by attempting several tests on them for their daily use. If a textile industry achieves the positive test report of such companies, its reputation shoots sky-high. The garment retailers can purchase their products without any suspicion of damage under particular conditions.

Companies like SGS S.A., Bureau Veritas, and Fiti testing and research institute are some famous names. A fabric sample is sent to such companies for examination. They run different tests on them, including various types of laundry/dry cleaning shrinkage tests. If and only if a particular piece of cloth passes all the given tests, then can it be given the status of ‘PASS,’ which is the ultimate goal of all the textile industries. Attire brands prefer purchasing fabrics from the industries certified by such companies.

A standard testing report should be like this:

How to control Fabric Shrinkage

Shrinkage control is the factor that is prioritized by the textile industries. Their entire game depends upon it. The shrinkage rate acts like a ‘ride or die’ for the brand’s future. Some characteristics of the clothing material that cause shrinkage are;

- Construction of the material

The rigid textures that are constructed with tight weaves reduce likely shrinkage.

- Twisting of yarn

The optimum twisting of yarn can help prevent excessive shrinkage.

- Type of weaves

A few types of weaves and knits show more resistance to shrinkage than the others.

- Tension build-up

While stitching a garment, if it is stretched way too much for the fabric to endure, it leads to differential shrinkage.

- Stability of fiber

Inappropriate stabilization of the fabric results in excessive shrinkage.

If these factors are not overlooked during fabric making, you can prevent 90 percent of shrinkage. There are plenty of ways to control fabric shrinkage; Some of the standard practices followed by the garment manufacturers are;

Manufacturer’s Way

It is an industrial process. The manufacturer’s way of controlling shrinkage is simple, and it goes with the flow. The workers in a particular textile industry make sure that the machine is working on correct parameters. The quality of the yarn is fine, and the conversion process is working smoothly. Usually, no force is applied to the clothes unless the machines are not entirely fit. The continuous examination for all the steps’ smooth functioning can ensure less than 5 percent of shrinkage in the product. So basically, step by step shrinkage reduction is the key. The lesser the shrinkage ratio is, after manufacturing the resultant texture, it is considered better and stable.

Mercerization

Mercerization is a procedure named after John Mercer, who introduced the textile industry with this chemical treatment. It is for cellulose fabric, cotton, and flax yarn. It can reduce fabric shrinkage. It is a standard procedure that is run on cotton fabric mainly. In this process, the fabric is exposed to caustic sodium hydroxide (NaOH), an alkaline solution. This treatment is carried out for a prolonged period. NaOH imparts a lot of positive changes in the clothes, including the reduction of shrinkage.

It has plenty of benefits ;

- Increases silky look

- Improves moisture absorption

- Increases the absorbance of dues

- Improves the clothe’s strength

- It makes the clothes smooth. Etc.

It is quiet on the pricier side as it takes a bit of cost in the production phase. That is why mercerized fabrics are costlier than regular un-mercerized natural or synthetic fabric. It was not in use until the 19th century. It has played a crucial role over the years in reducing the significant problems of fabric chemists.

A research article by several scholars explored the topic deeper about mercerization.

Preshrink Technique

Preshrinking is the favorite process of manufacturers to control fabric shrinkage. It is like a ritual that one should not miss. Every textile industrialist does it religiously. It is the most coming and easiest method of preventing shrinkage or more like reducing it. When a fabric is done with all the process and is ready to shine in the market, it is immersed in water by the workers. So that it can shrink as much as it can and save them from the embarrassment of shrinking after sewing. The purpose of pre-shrinking is to assure that the clothes dimension adjusts to what they are manufactured with. In this way, the industry succeeds in providing the best services to the customers.

Thermoplasticity

Thermoplasticity is another process aiming at the control of shrinkage. As the name shows, heat is involved in this process. It is the process designated for reducing shrinkage in synthetic fiber and resins like polystyrene and others. The process works by exposing the fabric to heat. Upon heating, it gets softened to the state of melting. Then it is cooled down. The cooling method makes the material hard again. It occurs in series—the loop of this process aids in lessening the rate of net decrease or increase in dimensions. The induction of thermal stress causes the plastic nature of the fabric to shrink as much as possible.

A research article named thermoplastic polyurethane technologies for the textile industry by Larry Johnson and Julie Samms could be a great reference.

Life Hacks

This is what goes behind in the industries to make the fabrics as user-friendly as they can. When purchasing a garment, you should check the labels where every detail is mentioned regarding washing techniques and other information. If you look for these few things before paying the bill for your favorite garment piece, you can save yourself from troubles. Make sure that you have seen the ‘pre-shrunk written on the label. Follow the washing and drying instructions.

Washing Instructions

- Washing in cold water can save you from the misery of dimensional loss or gain. The garments will fit you well before, but after a first wash, it becomes too tight to wear, and you end up blaming yourself for having cheat meals twice a week, but in actuality, your diet is not the problem.

- Hand wash the cotton, linen, and silk garments that can lose their spark if handled brutally in the washing machine with many other clothes like jeans and sweaters.

- Wash the clothes gently in the washing machine and not with the intense washing mode.

- Do not wash fabrics made out of animal-based fiber and get them dry cleaned instead.

Drying Instructions

- Some clothes can withstand the tumble dryers, but some can not, and their tiny fibers get ruptured, which looks awful. Similarly, you can airdry some clothes in the sun, but others can not, and their color fades away. To prevent such circumstances, go through the attached labels.

- Avoid drying multiple times and dry on the lowest heat.

These tips and tricks can prove to help prevent fabric shrinkage.

Conclusion

Earlier in the days, shrinkage was a rising problem that bothered every person, from producers to retailer owners and their clients. Over time, the division of so many chemical and physical processes has made it easier for the manufacturers to prevent shrinkage rate in the fabrics. For controlling shrinkage, it is necessary to understand its importance. It is like a nightmare for the textile industry. A partnership and a sense of understanding between the industry and the attire firm owners need achievement in the commercial centers. Mutual planning and compassion can lead to prosperity. To meet the product particulars, including the yarn, machine set-up, and coloring should be rightly picked. Simple facts and inappropriate decisions of construction parameters are an assurance for disappointment in the fight to control shrinkage of textures.